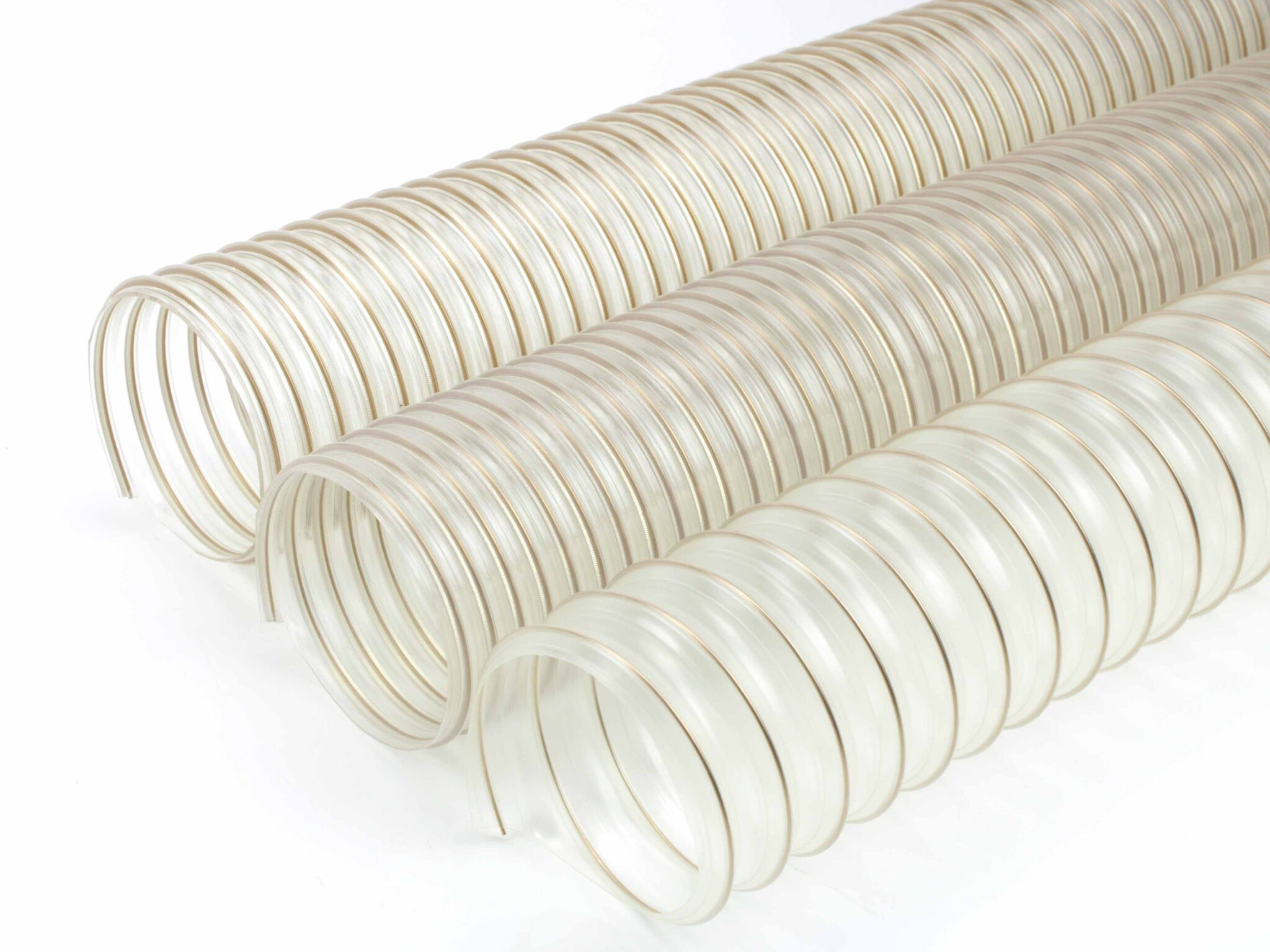

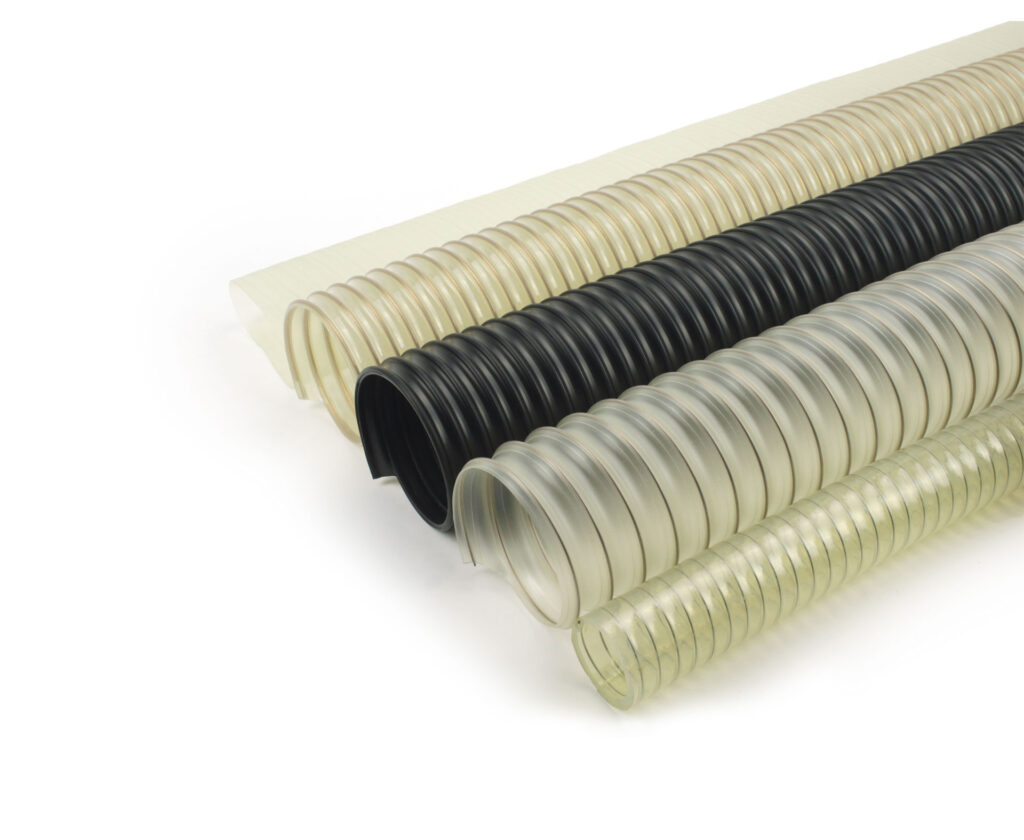

PUR polyurethane hoses

In this category you will find flexible transfer and extraction hoses made of wear‑resistant polyurethane (PUR) intended mainly for the transport of materials causing high abrasion, e.g. sawdust, powders, granules in extraction and feeding systems, as well as release of gaseous media and liquids.

PUR hoses offered

| Name | Intended use | Temperature resistance [°C] | Flammability class (acc. to UL94) | Surface resistance [Ω] | Color | Resistance to hydrolysis and microbes | Certificates and attestations | Spiral |

|---|---|---|---|---|---|---|---|---|

| PUR MB | transfer of loose abrasives | -30 ÷ +90 | V-II | ~109 | transparent | copper-plated spring wire | ||

| PUR EL | potentially explosive areas | -30 ÷ +80 | – | ~103 | black | Atest GIG* | copper-plated spring wire | |

| PUR TM | work at elevated temperatures | -30 ÷ +110 | V-II | ~109 | transparent | copper-plated spring wire | ||

| PUR AG | transmission of hydrolysis media | -30 ÷ +80 | V-II | ~109 | transparent | copper-plated spring wire | ||

| PUR SP | contact with food | -30 ÷ +90 | V-II | ~109 | transparent | Atest PZH** | stainless wire |

*Atest GIG – attestation issued by the Central Mining Institute

**Atest PZH – Health Quality Certificate. PUR SP hoses meet the requirements of EU Directive 2002/72 / EC, Regulation PE 1935/2004 regarding organoleptic features and global migration for model fluids A, B, C. Attention! Do not use for tranmission of fats.